Dyna-Tech

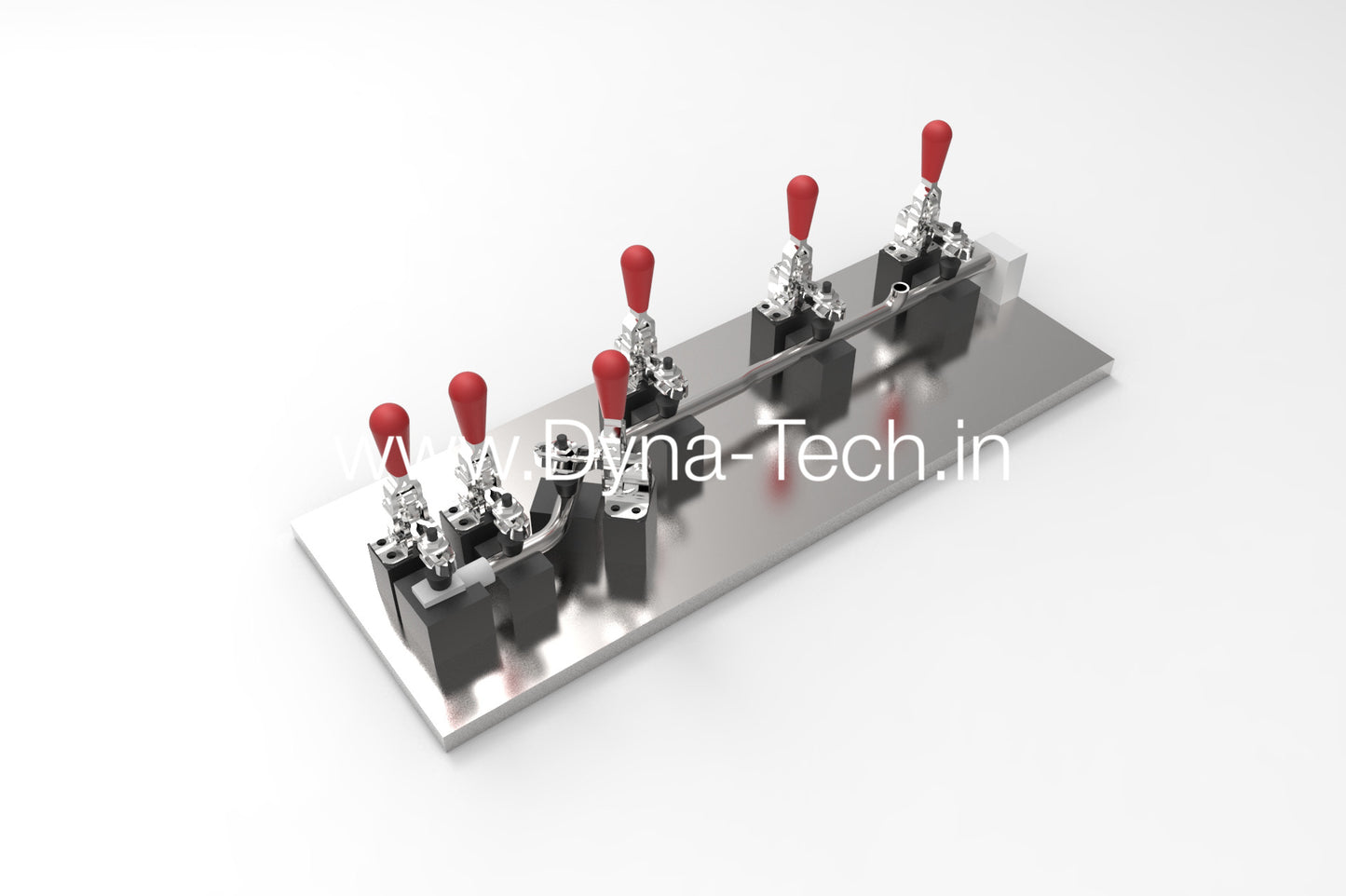

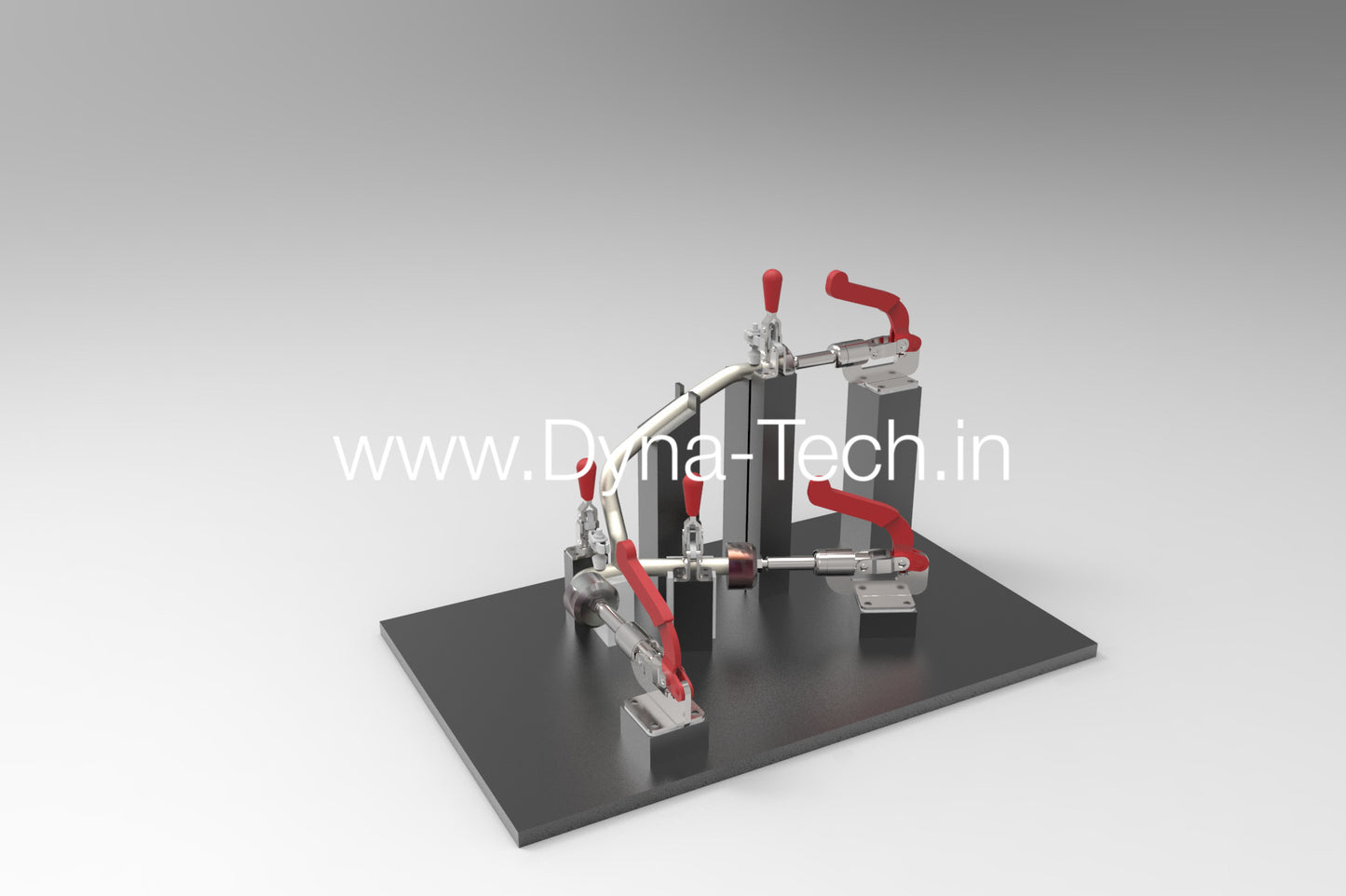

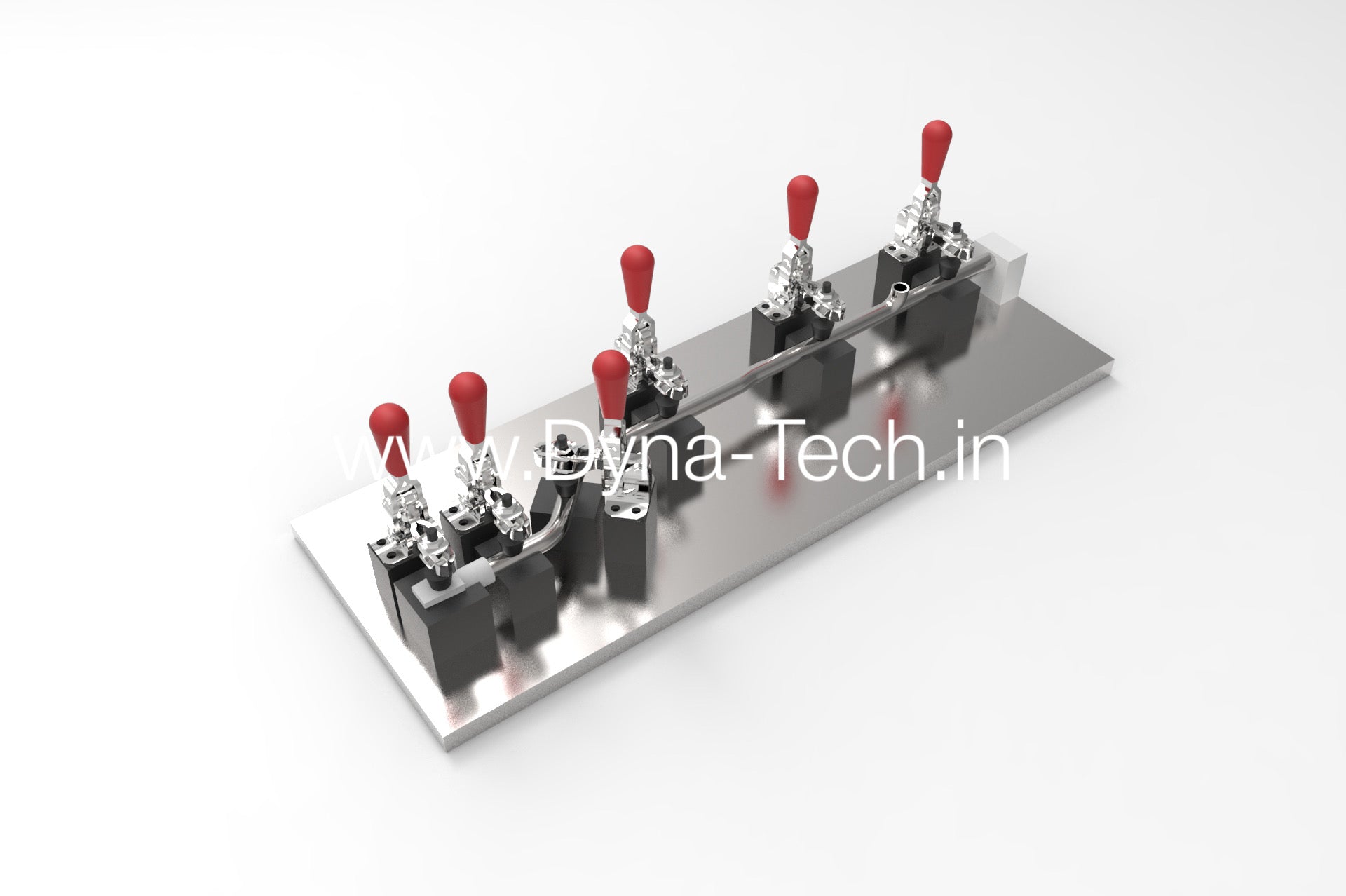

Custom Fixtures & Gauges - Design and Manufacturing Services

Custom Fixtures & Gauges - Design and Manufacturing Services

Couldn't load pickup availability

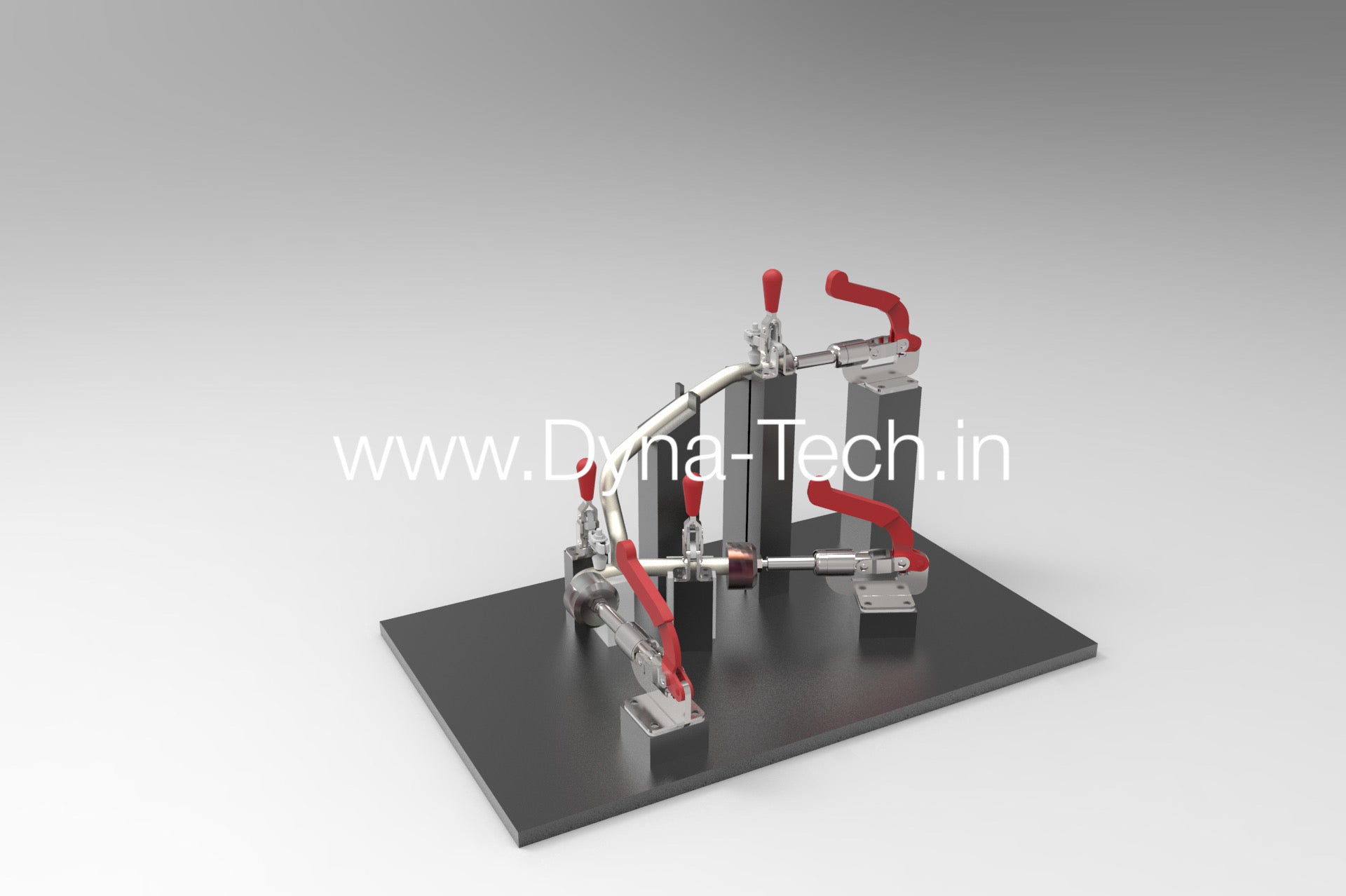

Precision fixtures and gauges designed and manufactured for automotive and component manufacturers.

Services:

- Assembly fixtures

- Welding fixtures

- Checking gauges

Advanced Capabilities:

- High-accuracy manufacturing with laser and 3D metrology

- In-house 3D scanning and 3D tracking guided assembly

- Cobot TIG welding for consistent quality

- Custom design to your specifications

Ideal for automotive manufacturers and child part suppliers requiring precision tooling solutions.

Materials

Materials

MOC: Stainless Steel

Shipping & Returns

Shipping & Returns

Dimensions

Dimensions

As per Requirements / Standard Optimised Dimesions

Usage SOP

Usage SOP

STANDARD OPERATING PROCEDURE (SOP)

Maximizing Life of Dyna-Tech Stainless Steel Foundry Tools

OBJECTIVE

To ensure long service life, consistent performance, and safe operation of Dyna-Tech stainless-steel foundry tools including pouring cups, skimmers, and funnels used for molten metal handling.

PROCEDURE STEPS

- PREHEATING

- Always preheat the tool uniformly to 250–300°C before first contact with molten metal.

- Use a gas burner or furnace preheater to eliminate surface moisture and prevent thermal shock.

- Never dip cold tools directly into molten aluminium.

- COATING APPLICATION

- Apply a non-wetting coating (TPT 120 or equivalent Boron Nitride-based coating) on all molten-metal contact surfaces (ID & OD).

- Use a brush or spray to achieve a uniform, thin layer.

- Allow proper drying or curing as recommended by the coating supplier before use.

- Reapply coating daily or whenever wear or metal sticking is observed.

- INSPECTION BEFORE USE

- Visually check for cracks, deformation, oxide scaling, or missing coating before every shift.

- Replace any damaged tools immediately to prevent metal contamination or tool failure.

- SKIMMING AND POURING PRACTICE

- Skim molten aluminium thoroughly before using any pouring or handling tool.

- Avoid dragging tools across the refractory floor; always lift and move smoothly.

- Maintain steady, controlled motion during pouring to minimize turbulence and metal splashing.

- HANDLING AND PLACEMENT

- Do not strike or scrape tools against the furnace or ladle walls.

- After use, place tools only on a heat-resistant stand or rack, never on a concrete or wet floor.

- Avoid contact with water or cool surfaces when hot.

- CLEANING AFTER EACH SHIFT

- When tools are warm (not hot), remove oxide or dross build-up using a soft wire brush or scraper.

- Do not grind or hammer the surface — this damages the protective coating and shortens tool life.

- Inspect coating condition and reapply if dull or worn.

- STORAGE

- Store tools in a dry, covered area free from moisture, flux residues, or corrosive vapours.

- Hang skimmers and smaller tools vertically; keep larger ones on wooden or insulated racks.

- Never stack tools directly on each other without separators.

- PERIODIC MAINTENANCE

- Perform a detailed inspection every week for wear, surface oxidation, or joint looseness.

- Recoat or refurbish as required.

- Record maintenance activity in the foundry tool log for traceability.

SAFETY PRECAUTIONS

⚠️ Always wear appropriate Personal Protective Equipment (PPE): ⚠️

- Face shield

- Heat-resistant gloves

- Leather apron

- Safety shoes

- Arm guards for extended pours